About Us

SHANTOU XINYU INDUSTRY CO.,LTD

Established year: 1998

Factory areas: 7139 (sq. meter)

Number of staffs: 112

Equipment: 22pcs injection machines at own factory

Products Category: Electronics Toy, Consumer Electronics (Audio & Mobile Accessories)

Customers base: U.S.A, EU, Southeast Asia, South America

Factory Audit : BSCI, SMETA, DISENY ILS, SCAN

Our factory boasts an exceptional and stable production supply chain, with each supplier having undergone rigorous auditing by Xinyu and maintaining years of collaboration with us. Xinyu’s stringent incoming quality control system ensures the high-quality of our materials. As a seasoned manufacturer of audio & toys, we have established a comprehensive team at our factory that includes technical engineers, purchasers, IQC (Incoming Quality Control), PMC (Production Material Control), warehouse management staff, shipping coordinators, and more.

Our Background

PRODUCTION LINES

Assemble/PackingLines:(Total: 5 lines)

25 m x 2 lines [For Audio Production]

16 m x 1 line [For Toy Production]

15 m x1 line [For Toy Production]

13 m x 1 line [For packing]

Our Facilities

INJECTION WORKSHOPS

NUMBER OF INJECTION MACHINES AT OWN FACTORY: (TOTAL: 22 SETS)

WAREHOUSE

OUR WAREHOUSES ARE LARGE ENOUGH TO ACCOMMODATE THE GROWING PRODUCTION CAPACITY WITH ALL KINDS OF RAW MATERIALS, SEMI-FINISHED AND FINISHED PRODUCTS.

LOADING AREA

OUR FACTORY IS A PRIVATE INDUSTRIAL PARK WITH AMPLE SPACE TO EFFICIENTLY ACCOMMODATE THE SIMULTANEOUS LOADING OF MULTIPLE CONTAINERS.

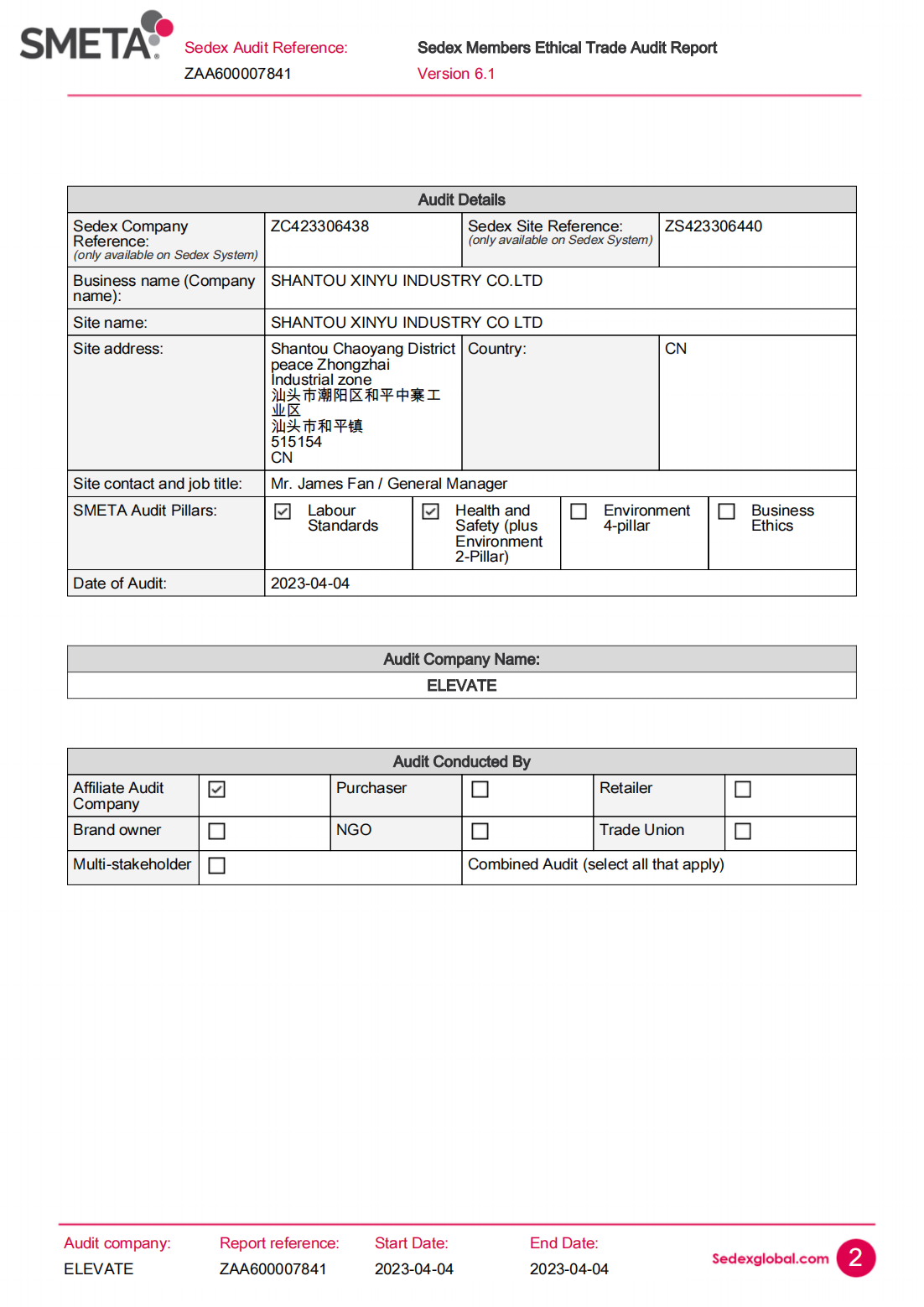

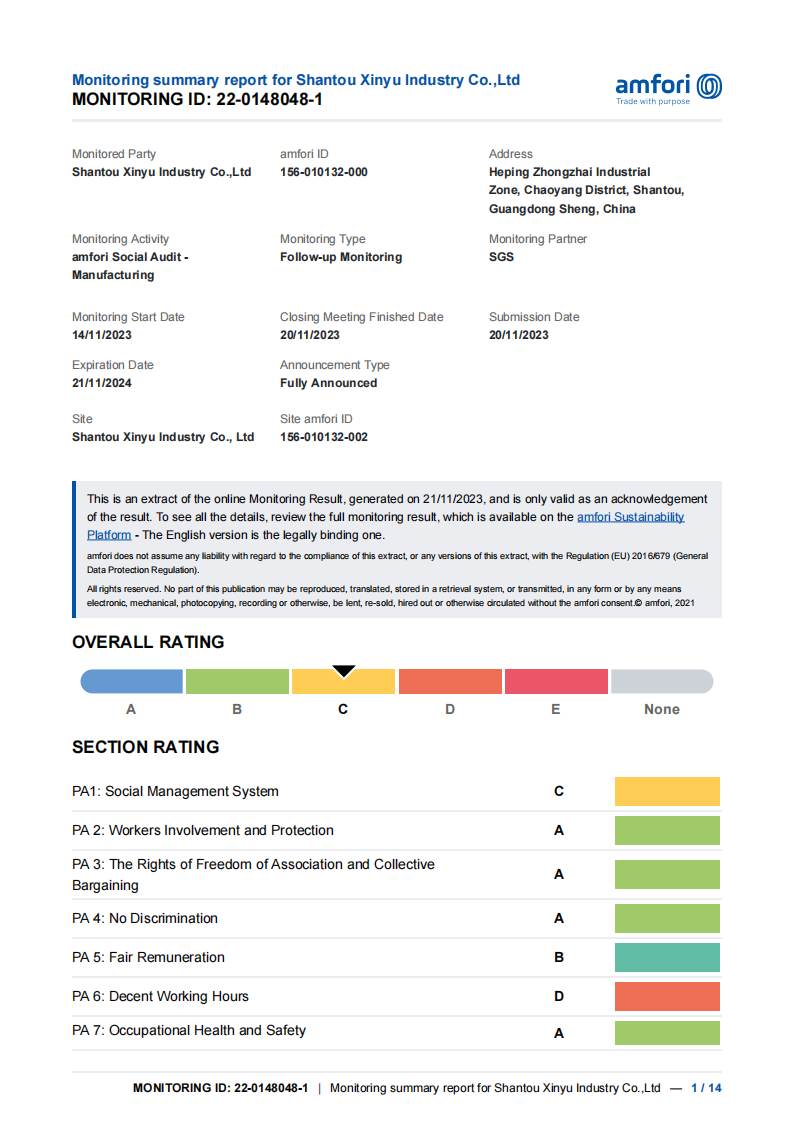

Xinyu Audit Reports

SMETA REPORT

BSCI REPORT

Frequently Asked Questions

For Ready Mold Items

MOQ is 3K units per colorways, and Lead time is 45 days after Order Confirmation

Yes, we can customize package based on your artwork file, and we will make PP samples for your approval before mass printing.

For New Product Development

We can develop new products by creating 3D drawings, making prototypes, and opening tooling based on your requirements. It takes 10 days for the 3D drawing, 14 days for making the functional prototype, and 35 days for opening the molds.

We will offer the tooling fee case by case. We can split the tooling fee into unit price or customer pay the tooling fee seperately. We will discuss with clients for providing the best solution

Partner Retailers